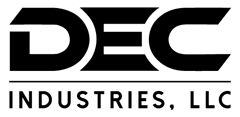

Metal Stamping, Casting,

Forging and Injection Molding

DEC Industries, LLC is a manufacturers' rep firm with with principals offering various metal manufacturing services. Helping OEM’s procure medium and high-volume engineered components from quality suppliers.

We want your toughest challenge. That is where we excel. Lately our niche has become helping customers solve existing problems.

Experience

|

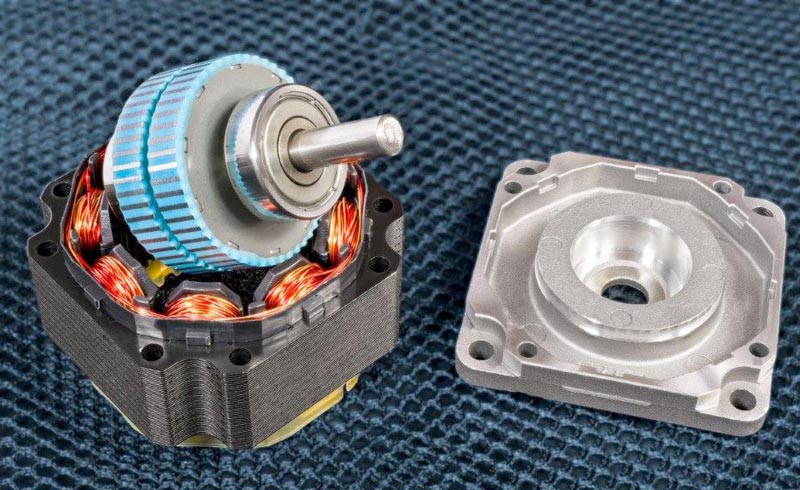

Over three decades of project management have enabled us to become a recognized specialist in the field of metal casting and manufacturing. Working with clients ranging from Aerospace, Automotive and Agriculture, to Medical, Defense and Marine, has required us to establish performance standards at the highest level of excellence - standards that we are excited to bring to your project.

Some of our sourcing experience includes:

|

How can DEC Industries Help? |

CommitmentWe welcome difficult design and manufacturing challenges. Our highly experienced team of suppliers employee industry leaders for engineers, designers and consistently deliver design and manufacturing solutions that exceed our client’s expectations. Working with clients in some of the world’s most competitive industries has also demanded that we develop high proficiency in working with short lead-times and an obsession with hitting production deadlines.

|

PartnershipDEC Industries, LLC is a dedicated partner that can take your production challenge from design concept through to delivered product, on time and within budget. We apply lean principles throughout every aspect of the process, eliminating waste and maximizing operational efficiency. Ensuring that you get precise, consistent product, and maximum value for your production dollar.

|

What Are We hearing from our customers

|

“The top of each category for quality, delivery and value for all of our TIER 1 suppliers”

|

“Really cares about us.”

|

“Thank you for the diligence and the excellent communication.”

|

“We have never been asked those questions before.”

|

Manufacturing Solutions

We help leading North American manufacturers in many areas, including:

|

CAPA Process (CORRECTIVE AND PREVENTIVE ACTION):* Problem identification

* Impact assessment * Containment * Investigate/Root Cause * Corrective Action * Verification * Closure |

DFM (DESIGN FOR MANUFACTURABILITY)

Design for Manufacturability is the engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase which is the least expensive place to address them. Other factors may affect the manufacturability such material, the form of the raw material, dimensional tolerances, and secondary processing such as finishing and machining.

DEC Industries uses this process to create the Best possible part at the BEST PRICE!

APQP (ADVANCED PRODUCT QUALITY PLANNING)

APQP serves as a guide in the development process and also a standard way to share results between suppliers and automotive companies. APQP specifies three phases: Development, Industrialization and Product Launch. Through these phases 23 main topics will be monitored. These 23 topics will be all completed before the production is started. They cover such aspects as: design robustness, design testing and specification compliance, production process design, quality inspection standards, process capability, production capacity, product packaging, product testing and operator training plan, among other items.

APQP focuses on:

APQP focuses on:

- Up-front quality planning

- Determining if customers are satisfied by evaluating the output and supporting continual improvement

|

APQP consists of five phases:

|

The APQP process has seven major elements:

|

PPAP (Production Part Approval Process)

Production Part Approval Process (PPAP) is the industry standard that ensures engineering design and product specification requirements are met. Through the PPAP guideline, suppliers and customers understand the requirements to obtain part approval of supplier manufactured parts. Applicable to all parts and commodities, application of these principles reduces delays and non-conformances during part approval.

|

What specific challenges does this address?

|

What are the benefits of PPAP?

|